Subsea pipeline - Case study 4

- iDG10 Engineering Solutions

- Sep 10, 2020

- 2 min read

Local buckling analysis during installation

Need for this analysis

The energy resources has facilitated the expansion of oil-gas exploration into deep-water regions. For these regions, the pipeline installation with S-lay approach is one of most common methods owing to its excellent adaptability and workability. In this pipelay technique, the pipes with designed lengths are fabricated on the vessel. The pipeline is then drawn by the tensioners and slides over the stinger to arrive at the seabed. The pipeline over the stinger is prone to local buckling, which requires to be assessed as per the limit state criteria of DNV-OS-F101 (Submarine Pipeline System). This case study presents FEA carried out to confirm the local buckling of the pipeline having D/t ratio outside DNV criteria is still acceptable,.

Our analysis method

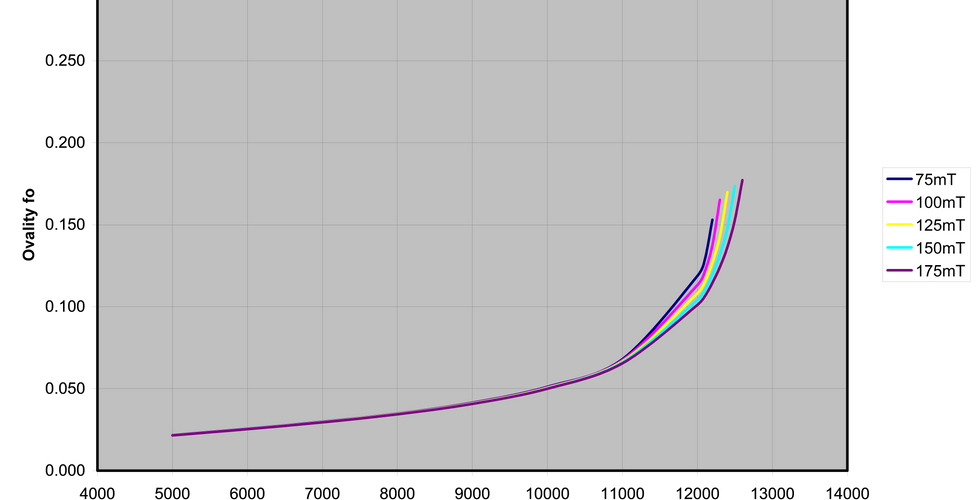

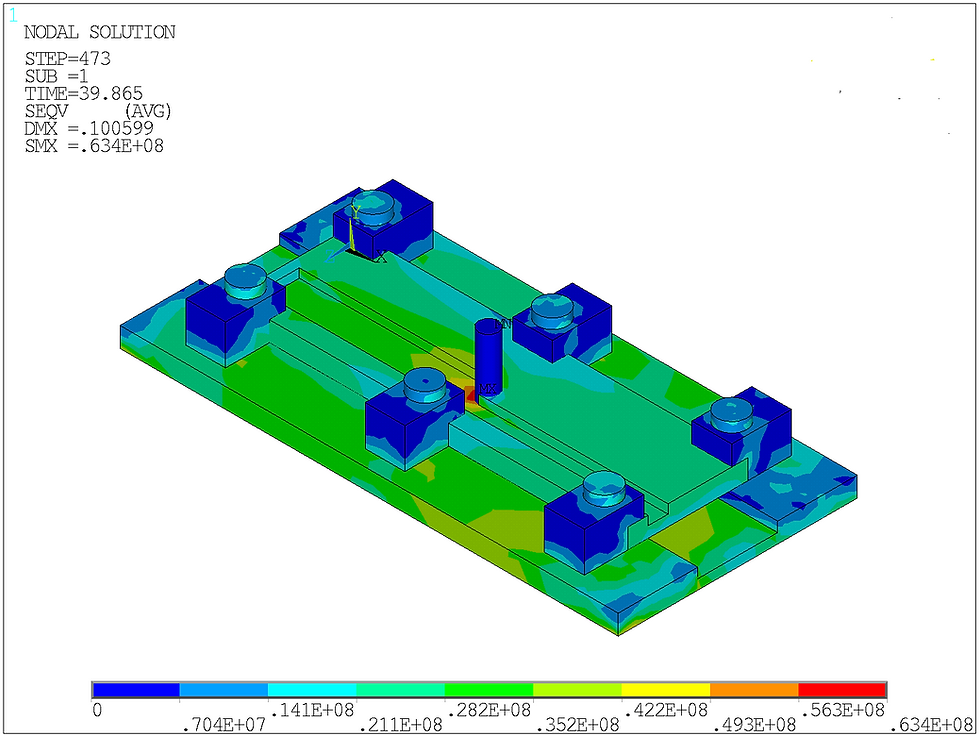

This case study presents finite element analysis of the 42” pipeline (Wall thickness = 18mm) with D/t ratio outside limit state criteria of DNV- OS-F101 (15≤𝐷/𝑡2≤45). The pipeline bending moment and deformation on the stinger during installation has been analysed with consideration of the pipe ovality and weld misalignment. The software OFFPIPE is generally used for the pipeline installation analysis using pipe beam model, which limits the use of this software for modelling misalignment. The analyses have been performed in ANSYS to quantify the pipeline bending moment and deformation capacity for the pipeline sections on the stinger during installation based on the combined loading criteria defined in DNV-OS-F101.

Displacement controlled criterion (DCC) applied for the overbend region

Load controlled criterion (LCC) applied to the sagbend region

Result

A detailed 3D FEA was carried out considering material/geometrical mismatch and pipe-roller contacts interaction in ANSYS. The sample results viz ovality vs bending moment, equivalent stresses are presented in figures below.

Comments