Offshore structure - Case study 1

- iDG10 Engineering Solutions

- Sep 25, 2020

- 1 min read

S-lay Stinger Design

Need for this analysis

The energy resources have facilitated the expansion of oil-gas exploration into deep water regions. For these regions, the pipeline installation with S-lay approach is one of most common methods owing to its excellent adaptability and workability. In this pipelay technique, the pipes with designed lengths are fabricated on the vessel. The pipeline is then drawn by the tensioners and slides over the stinger to arrive at the seabed.

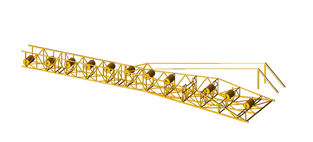

The stinger structure is composed of three main parts

Truss section

Intermediate section

Floating section

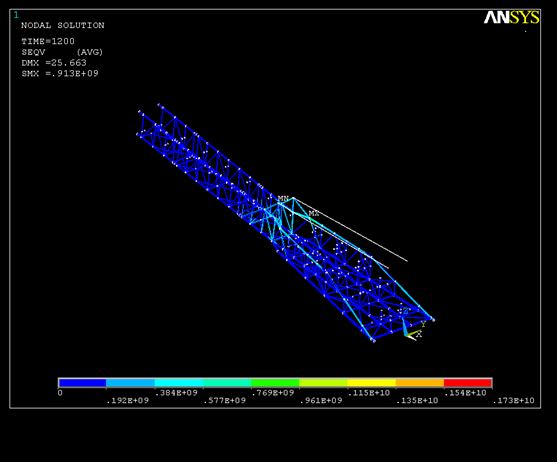

The stinger global assessment is performed to define the structure capability to withstand the environmental conditions and installation loads.

Our analysis method

The stinger design was analysed in ANSYS for the following :

Determine Dynamic Strength of the Structure

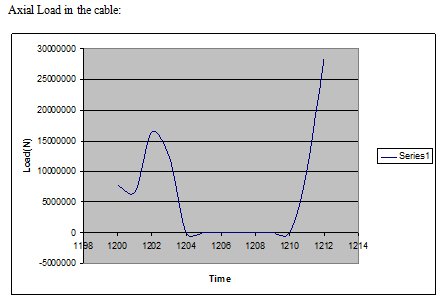

Establish Dynamic Loads for Handling Frame Design

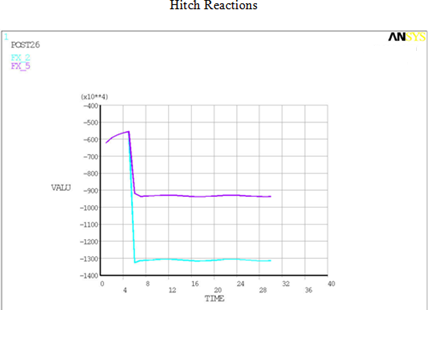

Establish Dynamic Loads for Stinger Hitch Design

Perform Detailed Static Analysis of Connections and Top-side

The stinger local analysis is performed to define detailed analysis on the most critical stinger locations identified by global analysis. This is to verify the integrity of the structural components and their load bearing connections.

Results

The SPDT offshore structure assessment module allows engineers to configure the FEA model by importing relevant model files configured in structural analysis software (SACS) and perform static/transient simulations.

In addition to analyzing stinger structure integrity, the input loads for the design of supporting frame, slings and stinger hitch were extracted.

The processed sample results are shown in figure below.

Comments